|

March 2: Milling out basswood for the shaft.

|

|

March 3: Snowshoed up the hill to get some

curved fresh branches for a grip. Got a few

from a maple tree top that recently blew down.

Also got a branch off a hemlock.

|

|

March 3 Decided to go with the hemlock it being

lighter in weight. Peeled and dried two sections

after sealing the ends with waterproof glue.

|

|

March 4: Glued the two half's of balsa together

to get 18" by 8". Then cut out the profile with

the bandsaw.

|

|

March 6: Glued up four strips of basswood to

form the shaft. There is a 1/2" square hole

down the center.

Added 16" plug into the blade end of the

shaft to allow blending the shaft with

the blade.

Cut the four corners off the rectangular

shaft to approximate an oval.

Cut a slot into the blade end of the shaft

for the balsa blade.

|

|

Worked the shaft into oval cross section with

draw knife and spokeshave for lower part.

Upper section nearing the grip area worked

it into round cross section.

|

|

March 10: Glued the blade into the end of the shaft;

using Titebond 3 waterproof glue.

Weight is now 13.5 oz

|

|

March 11: Ordered carbon fabric 5.7 oz 3k 2x2

Twill 50" wide. 24$ plus 6$ shipping.

March 15: Received fabric. Laid it out into 10

by 20 inch pieces, that will yield 7 pieces.

|

|

March 13: Epoxied 3/16" nylon cord around the

complete blade.

|

|

March 14: Mixed epoxy and basswood flour to

consistency of peanut butter. Used to form

the fillet between the shaft and blade.

Paddle weight is now 14.75 oz

|

|

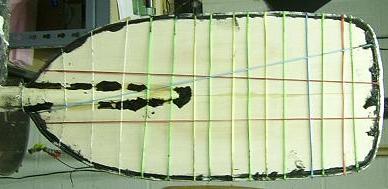

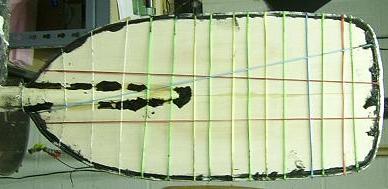

March 17: Added two layers of carbon fabric to

one face.

10;00 PM removed most excess fabric around edge of

blade while the epoxy is still green.

Weight: over 16 oz.

|

|

March 18: Added one layer of fabric to other side.

March 20: Still epoxying...now have three layers on

each side. Only two to go.

|

|

March 21: Added one layer of fiber glass on the side with only three carbon layers.

Added carbon powder to epoxy to get black surface. This will be the power face.

March 22: Added braided carbon biaxial sleeve to shaft.

Drilled hole in grip and glued plug into the shaft and grip. Coated the grip with

epoxy and carbon powder.

March 23: Sanding rough spots. Added a little epoxy, silica, and carbon powder to

rough area where the sleeving overlaps the blade.

Done. Weight....weighing both paddles crudely by balancing

on a dowel with bottle of water on the other end I get:

This paddle 31 ozs.

Same paddle in ash, cherry, and fiberglass 37.5 ozs.

Difference of only 6.5 ozs. equals 70$/6.5 ozs = 10.77$ per oz.

Next one will be basswood and fiberglass.

Cost: About 70$ for the materials.

Also see:

"Building a Carbon Fiber Greenland Paddle"

by Duane Strosaker.

|

My other projects:

Building a paper canoe

How to make a paddle from a log

How to make a kayak paddle from a log

|